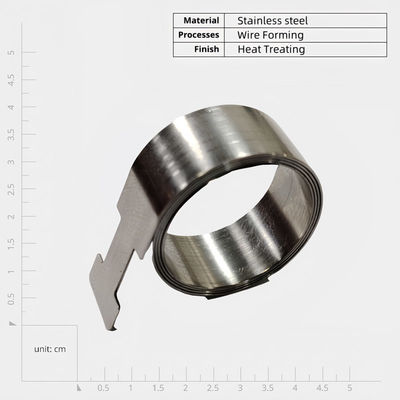

Product Description:

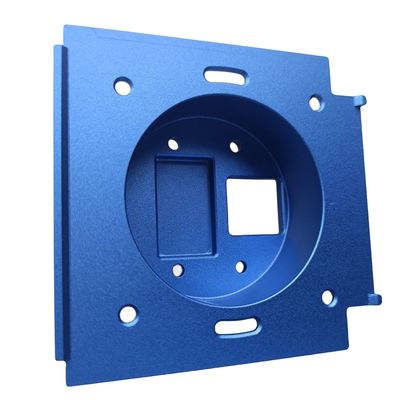

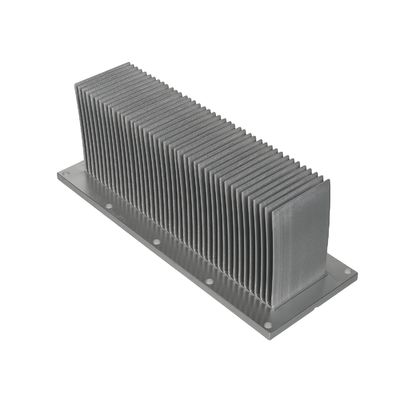

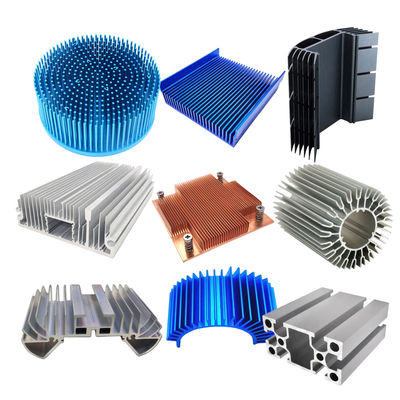

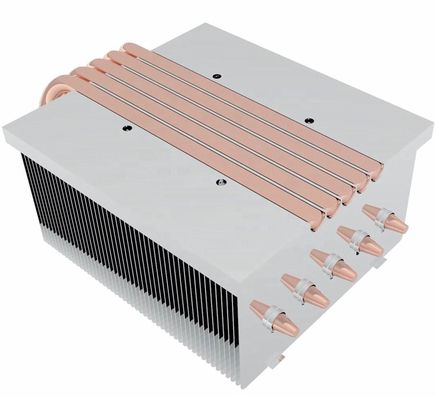

Our automotive precision machining capabilities are second to none. We work with a variety of materials, including stainless steel, aluminum, brass, and copper, and can machine parts to the exact specifications of our clients. Whether you need a small part or a large, complex assembly, we have the expertise and equipment to get the job done right.

Our high precision machining parts are made from materials that are carefully selected for their strength, durability, and reliability. We use original hardness materials with a hardness rating of HRC35-42 to ensure that our products can stand up to the toughest conditions. Our precision machining process is carefully controlled using variable frequency drives to ensure that our parts are made to the highest standards of accuracy and precision.

As a manufacturer and factory, we take pride in our work and are committed to delivering the best possible products to our clients. We work closely with our customers to understand their needs and develop solutions that meet their specific requirements. Our team of engineers and technicians are highly skilled and experienced in the field of precision machining, and are dedicated to delivering products of the highest quality.

Our high precision machined parts have a surface roughness of Ra 0.4-1.6 μm, which means that they are smooth and free of imperfections. This makes them ideal for use in a range of applications, including automotive, aerospace, and medical industries.

Whether you need a single part or a large quantity of parts, we are here to help. Contact us today to learn more about our high precision machined parts and how we can help you meet your manufacturing needs.

Features:

- Product Name: Precision Machined Parts

- Process: Turning/ Milling/ Grinding/ Machining

- Business Type: Manufacturer&factory

- Processing Type: CNC Machining

- Oem Or Odm: Available

- Original Hardness: HRC35-42

- Features:

- High Precision Parts

- Automotive Precision Machining

- High Quality Materials

- Expert Craftsmanship

- Customizable Designs

- Strict Quality Control

Technical Parameters:

| OEM/ODM |

Available |

| Business Type |

Manufacturer & Factory |

| Engineering |

CNC | Drilling Machines |

| Process |

Turning/Milling/Grinding/Machining |

| Original Hardness |

HRC35-42 |

| Surface Roughness |

Ra 0.4-1.6 μm |

| Quality Control |

100% Inspection |

| Processing Type |

CNC Machining |

| Custom Made |

Yes |

| Accuracy |

0.01mm |

Applications:

Our precision machined parts are suitable for a wide range of product application occasions and scenarios. These include:

- Automotive Industry: Our high precision machined parts are used in the automotive industry for manufacturing of engine parts, transmission parts, and braking systems. These parts require absolute precision and accuracy, and our products meet the original hardness of HRC35-42.

- Medical Equipment: Our precision machined parts are used in the medical industry for manufacturing of medical equipment, surgical instruments, and implants. These parts require high precision and accuracy, and our products meet the strict quality control standards of ISO9001/IATF16949/CE.

- Aerospace Industry: Our custom precision parts are used in the aerospace industry for manufacturing of aircraft components, rocket components, and satellites. These parts require 5 axis precision machining, and our products meet the highest quality control standards.

- Electronics Industry: Our precision machined parts are used in the electronics industry for manufacturing of electronic components, computer components, and communication equipment. These parts require absolute precision and accuracy, and our products meet the original hardness of HRC35-42.

- Industrial Equipment: Our custom precision parts are used in the industrial equipment industry for manufacturing of heavy machinery, pumps, and valves. These parts require high precision and accuracy, and our products meet the strict quality control standards of ISO9001/IATF16949/CE.

In conclusion, GuZhan Precision Hardware Co., LTD specializes in custom made 5 axis precision machining and high precision machined parts. Our products are suitable for a wide range of product application occasions and scenarios, and we provide 100% inspection and quality control to ensure the highest level of accuracy and precision. Contact us today for your precision machined parts needs!

Customization:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!