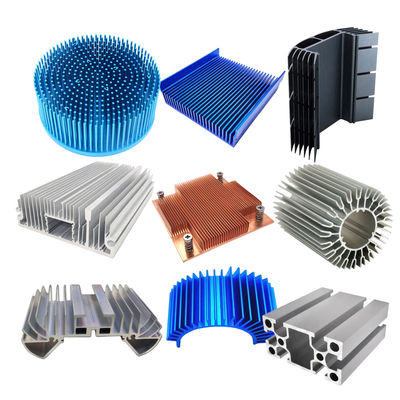

In the field of metalworking, selecting the appropriate material is crucial. Aluminum, known for its lightweight and corrosion-resistant properties, is widely used across various industries. However, with a plethora of aluminum alloy grades available in the market, choosing the most suitable one for machining has become a significant challenge for engineers and manufacturers. Among the common choices, 3003 and 6061 aluminum alloys stand out, each offering unique performance advantages and application scenarios. This article delves into the characteristics of these two alloys, compares their performance in machining, and provides guidance on material selection.

3003 Aluminum Alloy: The Benchmark for Versatility and Formability

3003 aluminum alloy is a manganese-based alloy renowned for its excellent formability and corrosion resistance. Compared to pure aluminum, 3003 offers improved strength while remaining a medium-strength material. Its superior workability makes it an ideal choice for manufacturing various general-purpose components.

The strength of 3003 aluminum can be enhanced through cold working, with different levels of cold working corresponding to different "tempers." The table below lists typical strength indicators for common 3003 tempers:

|

3003 Temper

|

Tensile Strength (KSI)

|

Yield Strength (KSI)

|

|

3003-O

|

19

|

6

|

|

3003-H12

|

23

|

18

|

|

3003-H14

|

26

|

21

|

|

3003-H16

|

30

|

25

|

|

3003-H18

|

27

|

27

|

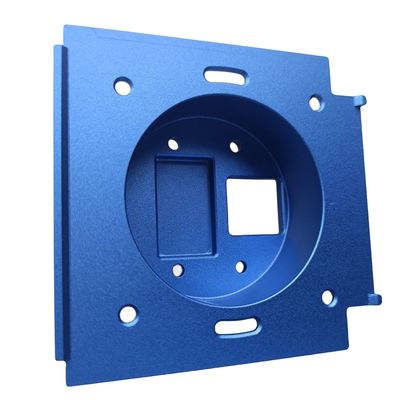

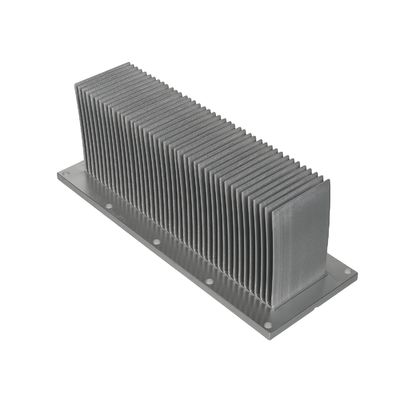

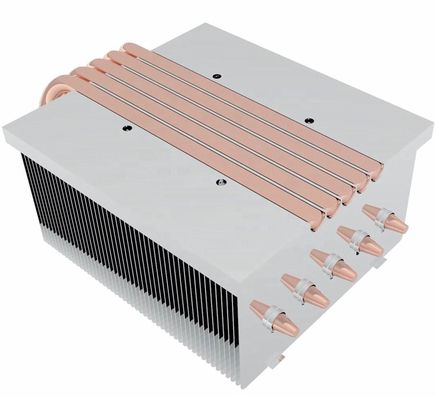

In addition to moderate strength, 3003 aluminum exhibits excellent corrosion resistance, machinability, and weldability. These properties make it an ideal choice for lightweight structural applications in industries such as aerospace, food processing, and chemical manufacturing. Common applications include:

-

Drainage systems

-

Folded sheet metal

-

Storage containers

-

Truck roofs

-

Heat exchangers

-

Pressure vessels

-

Acoustic ceilings

-

Downspouts

Despite its advantages, 3003 aluminum presents certain challenges in machining. Compared to harder aluminum alloys, its cutting performance is relatively poor. Furthermore, as a non-heat-treatable alloy, 3003 cannot achieve increased strength through precipitation hardening or similar heat treatment processes.

Being a cold-worked material, 3003 aluminum is prone to hydrogen-induced porosity during welding. To mitigate this issue, minimizing hydrogen absorption during welding is essential. This characteristic also makes 3003 unsuitable for extreme environment applications.

6061 Aluminum Alloy: The Perfect Balance of Strength and Versatility

6061 aluminum alloy is a widely used silicon-magnesium alloy known for its excellent corrosion resistance and favorable strength-to-weight ratio. It is a preferred material for marine and aerospace structures. Additionally, 6061 offers good electrical and thermal conductivity, making it suitable for electrical fittings, connectors, and magneto components.

6061 aluminum can undergo heat treatment to alter its properties, resulting in various tempers such as F, O, W, and T. Among these, the 6061-Tx series is most commonly used. In this designation, "T" indicates heat treatment, while "x" (typically a number) specifies additional processing. For instance, 6061-T6 undergoes solution heat treatment and artificial aging, offering good machinability and excellent weldability but poor formability. For applications requiring formability, 6061-T4 is ideal as it undergoes natural aging, providing good formability and weldability. In short, 6061 offers diverse tempers to meet a wide range of needs, whereas 3003 has relatively limited options.

6061 aluminum is frequently used in:

-

Bicycle frames

-

Beverage cans

-

Truck frames

-

Towers and utility poles

-

Aircraft components

-

Railway vehicles

Selecting Aluminum for Machining: 6061 or 3003?

To facilitate a direct comparison between 6061 and 3003 aluminum alloys, the table below summarizes their key properties:

|

Property

|

Aluminum 6061

|

Aluminum 3003

|

|

Tensile Strength

|

310 MPa

|

200 MPa

|

|

Yield Strength

|

276 MPa

|

186 MPa

|

|

Shear Strength

|

207 MPa

|

110 MPa

|

|

Brinell Hardness

|

95 HB

|

28 HB

|

|

Machinability

|

Good

|

Acceptable

|

|

Formability

|

Poor

|

Good

|

|

Weldability

|

Good

|

Good

|

|

Workability

|

Hot: Good, Cold: Excellent

|

N/A

|

In terms of formability, 3003 aluminum outperforms 6061, particularly in applications where design requirements demand excellent formability. For example, 3003 is ideal for outdoor architectural decorations, offering both formability and adequate strength to meet aesthetic needs. However, as a cold-worked alloy, it is unsuitable for structural applications requiring heavy machining.

Not all aluminum alloys are created equal. Most are produced to meet structural demands, such as automotive and aerospace frames and components, where strength-to-weight ratio is critical. In this regard, 6061 aluminum is one of the most common alloys, capable of fulfilling diverse requirements and making it one of the best choices for machining.

Machining Techniques and Best Practices

After selecting the appropriate aluminum alloy, employing proper machining techniques is equally important to ensure high-quality results. Below are some recommendations:

Tool Selection and Geometry

-

Choose carbide tools with a 35-45° helix angle to minimize heat generation and improve surface finish.

-

Opt for tools with no more than three flutes to ensure effective chip evacuation.

Cutting Speed and Feed Rate

-

Use high spindle speeds (up to 20,000 RPM) with moderate feed rates to prevent excessive heat buildup.

-

Refer to cutting speed calculators or manufacturer recommendations to determine optimal parameters.

Cooling and Lubrication

-

Apply suitable coolants or cutting fluids to the tool and workpiece to dissipate heat and improve chip removal.

-

Consider flood cooling or intermittent mist cooling techniques.

Chip Control

-

Monitor chip size and color to ensure proper chip formation and removal.

-

Use air blast systems or other chip removal methods to maintain a clean cutting area.

Advanced Machining Techniques

-

Implement adaptive clearing strategies to reduce cycle times and improve surface finish.

-

Utilize trochoidal milling to minimize tool engagement and prevent chatter.

When selecting aluminum for machining, corrosion resistance is a critical factor. Heat-treatable alloys like 6061 and 7075 offer excellent machinability and strength, but for applications where formability is paramount, 3003 is the preferred choice due to its superior formability. These commonly used alloys demonstrate versatility across industries, highlighting their broad applicability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!