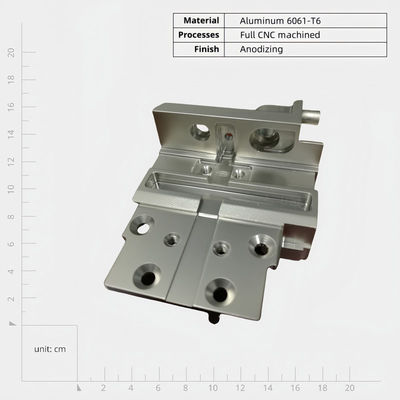

Product Description:

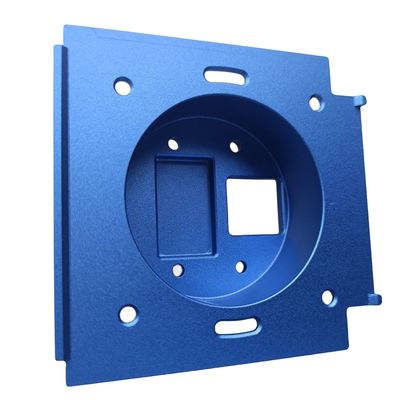

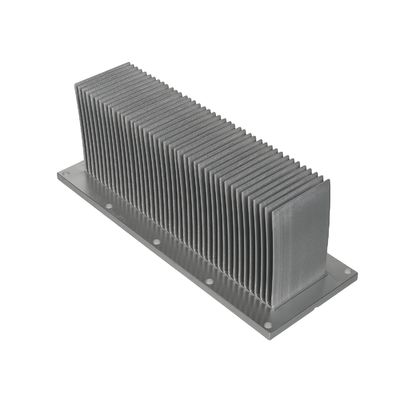

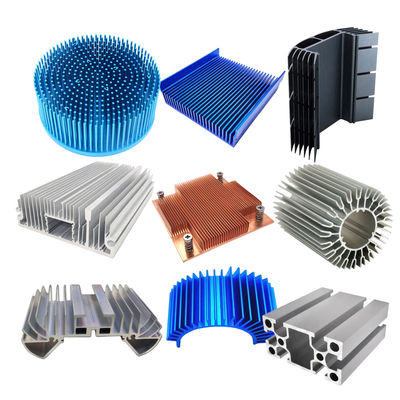

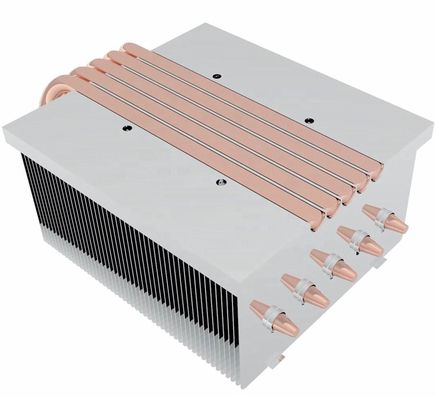

Our CNC Machined Housings are made from lightweight aluminum and copper materials, which are ideal for applications that require a strong and durable product. With our advanced CNC machining technology, we can create parts with high precision and accuracy, ensuring that every part is made to the exact specifications required.

If you are in need of high-precision mechanical parts, look no further than our CNC Machined Housings. Our advanced CNC machining technology, coupled with our commitment to quality and customization, makes us the perfect partner for all of your CNC custom parts needs.

Features:

- Product Name: CNC Machined Housings

- Material: Aluminum

- Type: CNC Machining

- Customization: Available

- Surface Finish: Anodized

- Heat Resistance: High

- Keywords: CNC Mechanical Parts, CNC Mechanical Part, CNC Medical Parts

Technical Parameters:

| CNC Auto Parts |

CNC Mechanical Part |

| Assembly |

Easy |

| Material |

Aluminum |

| Finish |

Anodized,Chromating Passivation |

| Surface Treatment |

Anodized |

| Customization |

Available |

| Dimensions |

Customized |

| Heat Resistance |

High |

| Lead Time |

7-15 Days |

| Weight |

Lightweight |

| Precision |

High |

| CNC Machined Components |

|

Applications:

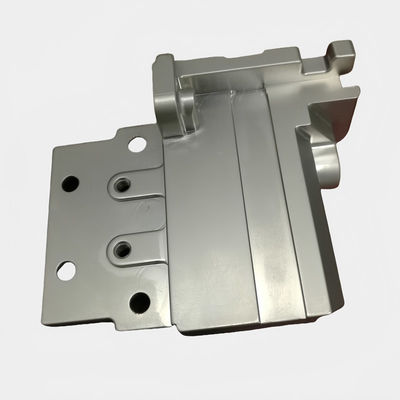

One of the primary applications of this CNC Mechanical Part is in the mechanical industry, where it can be used in various equipment, including engines, pumps, and other machinery. With its customized dimensions and easy assembly design, this product can be integrated seamlessly, providing a reliable and long-lasting solution for mechanical equipment. In addition, the use of anodized and chromating passivation finish enhances its corrosion resistance, making it ideal for harsh environments where corrosion is a significant issue.

CNC Medical Parts require high precision and accuracy, and this CNC Machined Housing product is well-suited to meet those requirements. It can be used in a range of medical equipment, including surgical tools, implants, and diagnostic equipment. The product's high-quality manufacturing standards and customizable dimensions make it a perfect solution for various medical applications.

CNC Custom Parts are widely used in different industries, and this CNC Machined Housing product is no exception. Its easy assembly design makes it suitable for various applications, including aerospace, automotive, and electronics. With its anodized surface finish, this product can be used in environments with high temperatures and frequent exposure to moisture.

With a minimum order quantity of 500 and a supply ability of 10000 pcs/M, this CNC Machined Housing product is readily available and can be delivered within 15~20 days. The payment terms include L/C and T/T, providing flexibility to customers. Moreover, the product is customizable, enabling customers to get the exact specifications that meet their specific requirements.

Customization:

Our CNC Custom Parts are lightweight, easy to assemble, and available for customization to meet your specific needs. We offer customized dimensions and surface treatments, including anodizing. Whether you need CNC Custom Parts for automotive, aerospace, or other industrial applications. Don't settle for subpar CNC Mechanical Parts - choose Guzhan Precision for precision, quality, and reliability.

Support and Services:

Our CNC Machined Housings are designed to meet your specific requirements and are manufactured to the highest standards. We provide technical support and services to ensure that your CNC Machined Housing operates at maximum efficiency and productivity. Our services include:

- Design and Engineering Support

- Machine Programming

- Manufacturing and Assembly

- Testing and Inspection

- Repair and Maintenance

We are committed to providing you with the best possible support and services to ensure that your CNC Machined Housing performs at its best.

FAQ:

1. Where is your factory?

We are in DongGuan, China.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings? Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!