Imagine molten metal flowing like lava, instantly injected into precision molds where intricate metal components take shape within seconds. This is the magic of die casting – an efficient, cost-effective metal forming process that bridges raw materials to finished products, serving as an indispensable link in modern manufacturing.

Behind this seemingly simple process lie two fundamentally different technical approaches: hot chamber die casting and cold chamber die casting. Like rival martial arts schools, each method has distinct advantages tailored for different metal materials and production requirements. Which technique prevails? Let's examine these competing metal-forming methodologies.

Die Casting: The Most Direct Path for Metal Forming

Die casting represents a highly efficient metal forming process where molten metal is injected under high pressure into reusable metal molds, rapidly producing components with precise dimensions and excellent surface finishes. As the most direct path from raw material to finished product, die casting can create ready-to-use metal parts without secondary machining, making it one of the most widely used metal processing techniques today.

Compared to traditional metalworking methods like casting, forging, and machining, die casting offers multiple advantages:

- High efficiency: Rapid production of large quantities of metal components significantly reduces cycle times.

- Precision: Achieves exceptional dimensional accuracy and surface quality, minimizing post-processing requirements.

- Complex geometries: Capable of producing intricate, finely detailed metal parts for diverse design needs.

- Cost-effectiveness: Reduces material waste and labor costs, lowering overall production expenses.

These benefits have established die casting as a critical manufacturing technology across automotive, aerospace, electronics, appliances, and machinery industries.

Hot Chamber vs. Cold Chamber: Origins and Evolution

Based on molten metal handling methods, die casting divides into two primary types: hot chamber and cold chamber processes. Both techniques trace their origins to the late 19th century when industrial revolution demands outpaced traditional metalworking capabilities.

- Hot chamber die casting: Originally developed for typeface printing, this method evolved into a standalone process where the metal melting furnace integrates directly into the die casting machine, injecting molten metal directly from the furnace into molds.

- Cold chamber die casting: Developed to address high-melting-point metals, this approach relocates metal melting outside the casting machine, preventing equipment corrosion from high-temperature metals.

Both technologies have undergone continuous refinement in materials, equipment, and processes, expanding their industrial applications.

Cold Chamber Die Casting: Shaping High-Temperature Metals

Despite its name, cold chamber die casting doesn't use cold metal – rather, the melting occurs separately from the casting machine. Metal first melts in an external furnace before being transferred (manually or mechanically) to the casting machine's injection chamber. A plunger then forces the molten metal into molds under high pressure for solidification.

Cold Chamber Process:

- Melting: Metal melts in an external furnace

- Transfer: Molten metal moves to the injection chamber

- Injection: Plunger forces metal into molds under pressure

- Solidification: Metal cools rapidly in the mold

- Ejection: Mold opens to remove the casting

- Preparation: Mold cleaning for next cycle

This separated melting process makes cold chamber die casting ideal for higher-melting-point metals like aluminum, magnesium, and copper that could damage internal machine components.

Preferred Materials:

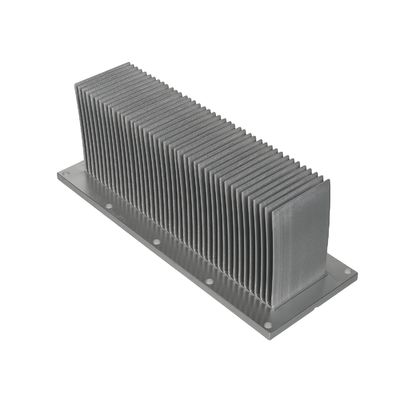

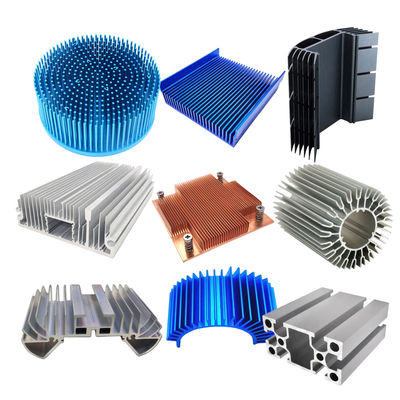

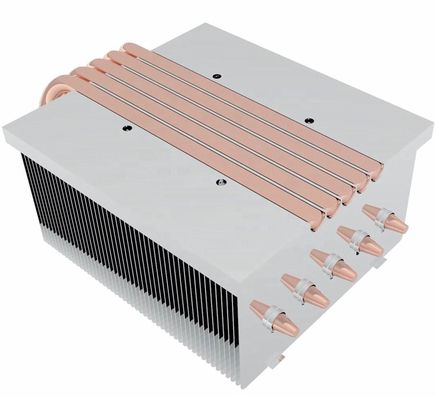

- Aluminum alloys: Excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity

- Magnesium alloys: Lightest structural metal with good vibration damping

- Copper alloys: Superior electrical conductivity and corrosion resistance

- Zinc alloys: Sometimes used for enhanced performance

Common Applications:

- Automotive: Engine blocks, transmission cases, wheels

- Aerospace: Structural components, engine parts, electronics housings

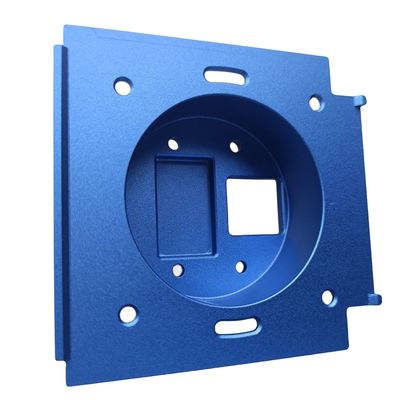

- Electronics: Device enclosures, heat sinks, connectors

- Machinery: Various mechanical components and equipment housings

Hot Chamber Die Casting: Efficiency for Low-Temperature Metals

In contrast, hot chamber die casting integrates the melting furnace directly into the casting machine. Metal melts internally before a hydraulically-driven piston injects it into molds – the defining characteristic of this approach.

Hot Chamber Process:

- Melting: Metal melts in the integrated furnace

- Injection: Piston forces molten metal into molds

- Solidification: Rapid cooling in the mold

- Ejection: Mold opens to remove casting

- Preparation: Mold cleaning for next cycle

This integrated system suits lower-melting-point metals like tin, zinc, and lead alloys that won't damage internal components. The unified melting/casting process typically delivers higher production rates than cold chamber methods.

Preferred Materials:

- Zinc alloys: Excellent castability, mechanical properties, and corrosion resistance

- Tin alloys: Superior fluidity and solderability

- Lead alloys: High density and corrosion resistance

Common Applications:

- Electronics: Components, connectors, housings

- Toys: Parts and models

- Hardware: Lock bodies, cores, keys

- Decorations: Ornaments and accessories

Comparative Analysis: Strengths and Limitations

Cold Chamber Advantages:

- Handles high-temperature metals (aluminum, magnesium, copper)

- Produces denser castings with superior mechanical properties

- Excellent corrosion resistance and thermal conductivity

- Lower maintenance costs with competitive pricing

Cold Chamber Disadvantages:

- Longer cycle times due to metal transfer requirements

- Higher oxidation risk during metal transfer

- Greater equipment investment (external furnaces)

- Increased labor requirements

Hot Chamber Advantages:

- Faster production cycles (up to 15 cycles/minute)

- Lower production costs for high-volume runs

- Higher material utilization with efficient mold designs

- Reduced porosity and extended mold life

Hot Chamber Disadvantages:

- Limited to low-temperature metals

- Restricted part complexity due to metal flow limitations

- Requires higher pressure ranges

- Economical only for large production volumes

Key Differences at a Glance

| Feature |

Cold Chamber |

Hot Chamber |

| Suitable Metals |

High-temperature (aluminum, magnesium, copper) |

Low-temperature (zinc, tin, lead) |

| Melting Location |

External to machine |

Integrated in machine |

| Production Speed |

Slower |

Faster |

| Cost Efficiency |

Medium-volume production |

High-volume production |

| Part Complexity |

Higher |

Lower |

| Oxidation Risk |

Higher |

Lower |

| Equipment Investment |

Higher |

Lower |

| Mold Longevity |

Longer |

Shorter |

Selecting the Optimal Process

Choosing between these methods requires evaluating several factors:

- Material: Metal type dictates available options (cold chamber for high-temperature metals)

- Volume: Hot chamber excels in mass production, cold chamber for medium runs

- Budget: Cold chamber has higher upfront costs but lower maintenance

- Timeline: Hot chamber offers faster turnaround

- Complexity: Cold chamber accommodates more intricate designs

- Performance: Mechanical properties and corrosion resistance requirements

Future Directions in Die Casting

Emerging technologies are advancing die casting capabilities:

- High-vacuum die casting: Reduces porosity for improved density and strength

- Semi-solid casting: Lowers metal temperatures to minimize oxidation

- Precision casting: Enhances dimensional accuracy and surface finishes

- Smart casting: Implements automation and data analytics

- Green casting: Reduces energy consumption and environmental impact

Conclusion: Choosing Your Metal-Forming Discipline

Like complementary martial arts styles, hot chamber and cold chamber die casting each excel in specific applications. The optimal choice depends on your production requirements – whether prioritizing high-temperature metal capabilities (cold chamber) or rapid, cost-efficient production of lower-temperature components (hot chamber). Understanding these fundamental differences enables manufacturers to select the most appropriate metal-forming methodology for their specific needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!