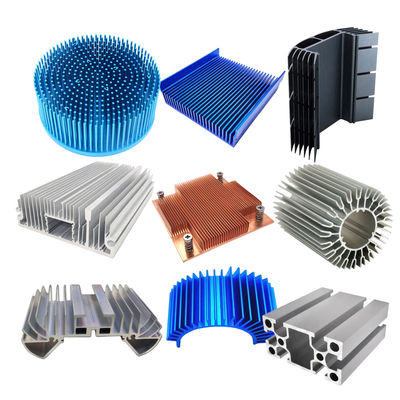

In the competitive landscape of product development, time is often the decisive factor between success and failure. The ability to quickly transform design concepts into tangible, testable prototypes has become crucial. Rapid Prototyping (RP) has emerged as a powerful solution, dramatically accelerating the journey from concept to reality. This comprehensive guide examines eight leading rapid prototyping technologies, analyzing their principles, advantages, limitations, and ideal applications.

Understanding Rapid Prototyping

Rapid Prototyping, also known as Rapid Manufacturing or Additive Manufacturing (AM), refers to technologies that quickly create physical models to validate design, functionality, and manufacturing feasibility. Unlike traditional subtractive methods like CNC machining, rapid prototyping typically builds objects layer by layer directly from CAD models.

The significance of rapid prototyping includes:

-

Reduced development cycles: Models can be produced in hours or days rather than weeks.

-

Lower development costs: Early identification of design flaws prevents expensive modifications later.

-

Design optimization: Enables rapid iteration and evaluation of multiple design approaches.

-

Improved communication: Physical models facilitate clearer demonstration of product features to stakeholders.

Eight Leading Rapid Prototyping Technologies

1. Stereolithography (SLA)

Principle: Uses ultraviolet lasers to cure liquid photopolymer resin layer by layer.

Advantages:

-

Exceptional precision and surface finish

-

Wide material selection with various resin formulations

-

Mature, widely available technology

Limitations:

-

Relatively low part strength

-

UV sensitivity of finished parts

-

Requires support structures

Applications: Concept models, precision molds, medical models

2. Fused Deposition Modeling (FDM)

Principle: Extrudes thermoplastic filaments through heated nozzles to build layers.

Advantages:

-

Low equipment and material costs

-

Simple operation and maintenance

-

Diverse thermoplastic options

Limitations:

-

Visible layer lines and moderate surface quality

-

Anisotropic mechanical properties

-

Support structures required

Applications: Basic prototypes, educational use, customized products

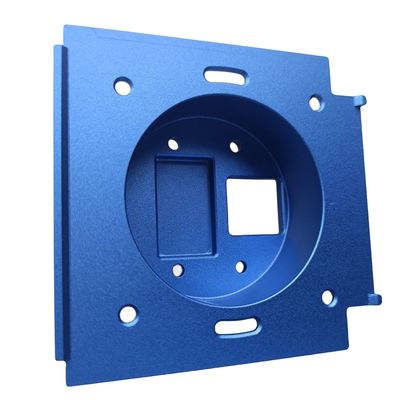

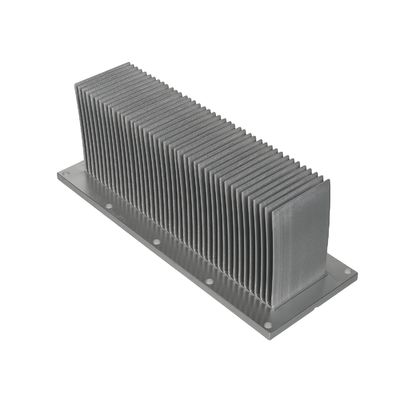

3. Computer Numerical Control Machining (CNC)

Principle: Subtractive process using computer-controlled cutting tools.

Advantages:

-

Superior precision and surface finish

-

Broad material compatibility including metals

-

High-strength functional parts

Limitations:

-

Higher equipment costs

-

Material waste from subtractive process

-

Geometric complexity limitations

Applications: Functional prototypes, precision molds, small batch production

4. Selective Laser Sintering (SLS)

Principle: Uses lasers to fuse powdered materials layer by layer.

Advantages:

-

Strong functional parts

-

No support structures needed

-

Variety of powder materials available

Limitations:

-

Rough surface texture

-

Moderate precision

-

Higher material costs

Applications: Functional testing, small batch production, customized products

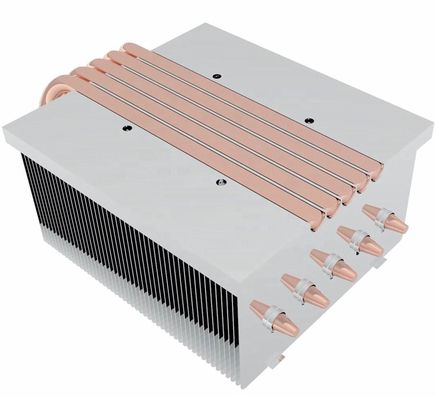

5. Direct Metal Laser Sintering (DMLS)

Principle: Laser-based sintering of metal powders.

Advantages:

-

Exceptional part strength

-

Complex geometries possible

-

Multiple metal material options

Limitations:

-

Very high equipment and material costs

-

Surface finishing required

-

Moderate precision

Applications: Aerospace components, medical implants, high-performance automotive parts

6. Multi Jet Fusion (MJF)

Principle: Uses inkjet arrays to deposit fusing and detailing agents on powder beds.

Advantages:

-

Faster than SLS

-

Good mechanical properties

-

Better surface quality than SLS

Limitations:

-

Limited material selection

-

Higher costs

-

Color limitations

Applications: Functional prototypes, small batch production, customized products

7. PolyJet Technology

Principle: Jets photopolymer materials cured by UV light.

Advantages:

-

High precision and surface quality

-

Multi-material and full-color capability

-

Minimal post-processing

Limitations:

-

Limited part strength

-

Higher material costs

-

Expensive equipment

Applications: Concept models, medical models, multi-material prototypes

8. Rapid Injection Molding

Principle: Uses aluminum molds for small batch injection molding.

Advantages:

-

Lower mold costs than steel

-

Faster mold production

-

Wide thermoplastic selection

Limitations:

-

Shorter mold lifespan

-

Moderate precision

-

Not suitable for mass production

Applications: Small batch production, functional testing, bridge production

Selecting the Right Technology

Choosing the optimal rapid prototyping method requires consideration of several factors:

-

Precision needs: SLA, CNC, or PolyJet for high accuracy

-

Strength requirements: CNC, SLS, or DMLS for durable parts

-

Material specifications: Match material properties to application

-

Budget constraints: Costs vary significantly between technologies

-

Timeline: Some methods offer faster turnaround

-

Production volume: Rapid injection molding for small batches

Future Developments

Rapid prototyping continues to evolve with several emerging trends:

-

Expansion of material options including ceramics and composites

-

Increased automation and intelligent process control

-

Tighter integration with CAD/CAM and simulation tools

-

Broader applications in biomedical, architectural, and artistic fields

Conclusion

Rapid prototyping has become an indispensable element of modern product development. By selecting appropriate technologies, companies can significantly reduce development timelines, lower costs, and optimize designs. As these technologies continue advancing, their role in manufacturing and product innovation will only expand further.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!