Have you ever wondered how to perfectly combine seemingly unrelated materials like copper and wood to create functional yet artistic bottle stoppers? This article delves into the turning process of copper-wood barrel-style stoppers, examining how to optimize each step through data analysis to improve production efficiency and product quality.

Imagine an elegant copper-wood barrel stopper quietly guarding your prized wine collection. More than just a simple tool, it becomes a distinctive work of art that adds unique character to your lifestyle—all achieved through masterful turning techniques and meticulous attention to detail.

I. Material Preparation and Data Analysis

1. Wood Selection

-

Original Dimensions:

Select wood blocks measuring at least 1.75 inches square and 8 inches long, with sufficient length allowance for subsequent operations. Record parameters like density and moisture content for analyzing their impact on turning results.

-

Wood Types:

Recommended species include maple and cherry wood, known for their clear grain patterns and hardness. Maintain a wood database documenting turning parameters (speed, feed rate) and final quality for different species.

-

Cutting Plan:

Divide the wood into five slices—one center piece at 1/2 inch thickness and four others at 1/4 inch each. Maintain precision within 0.01-inch tolerance and record actual measurements for error analysis.

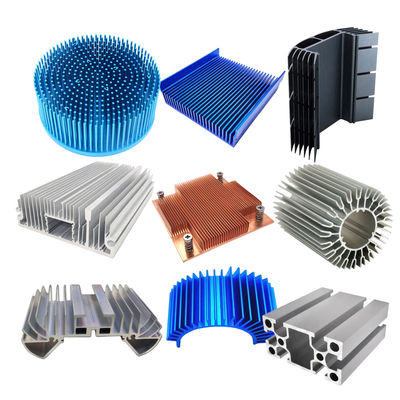

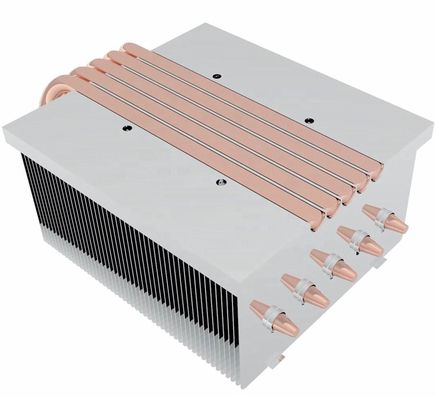

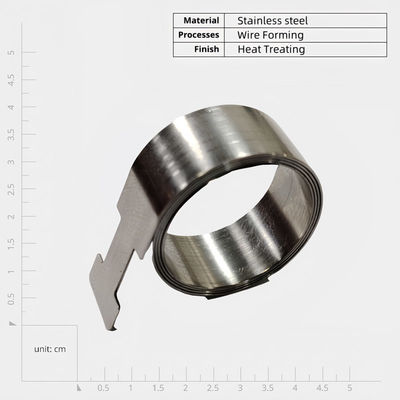

2. Copper Selection

-

Specifications:

Use 1/8-inch thick copper plates cut into 1.75-inch squares matching wood dimensions. Document how different thicknesses affect stopper strength and appearance.

-

Material Types:

Pure copper or brass offer excellent workability and luster. Create a copper material database recording hardness, ductility, and corresponding turning parameters.

3. Data Analysis

-

Error Analysis:

Calculate cutting deviations and assess their impact on final products to optimize precision.

-

Material Combination Optimization:

Analyze turning results for different wood-copper pairings to identify ideal combinations, such as harder woods with more ductile copper alloys.

II. Bonding Process and Quality Monitoring

1. Surface Preparation

Sand copper surfaces with 80-grit paper to increase roughness for better adhesion. Record bonding strength at different roughness levels to determine optimal preparation.

2. Adhesive Selection

Polyurethane adhesive outperforms PVA glue for non-porous materials, offering superior waterproofing and corrosion resistance for long-term durability. Document bonding strength and curing times across adhesive types.

3. Bonding Procedure

Moisten all surfaces, apply polyurethane adhesive, and clamp until fully cured while monitoring pressure to prevent deformation. Record clamping force and curing conditions for process optimization.

4. Quality Control

-

Conduct pull tests to verify bond strength meets specifications

-

Monitor curing times under various temperature/humidity conditions

III. Turning Process and Parameter Optimization

1. Thread Insert Installation

Drill 5/16-inch holes using a Jacobs chuck, apply polyurethane adhesive, and press 3/8-inch threaded inserts using the lathe's live center. Document hole-insert fitment data for process improvement.

2. Temporary Fixturing

Secure wood blocks with hot glue for stability, selecting adhesives based on strength and easy removal characteristics.

3. Turning Techniques

-

Tool Selection:

Standard carbide inserts perform exceptionally on copper. Maintain a tool database tracking performance across materials.

-

Speed Control:

Copper turning requires patience—precisely regulate lathe speed to prevent workpiece ejection or tool damage.

-

Feed Rate Management:

Focus on copper ring areas, removing material gradually while monitoring tool wear patterns.

4. Process Optimization

Record turning parameters (speed, feed rate, tool type) and correlate with finished quality. Use statistical analysis to establish optimal parameter combinations, potentially developing predictive models for surface finish quality.

IV. Finishing and Quality Assurance

1. Groove Carving

Use 1/4-inch parting tools to create wood grooves allowing copper rings to protrude slightly, achieving the barrel visual effect. Document groove dimensions for aesthetic optimization.

2. Edge Refinement

Gently round copper edges with parting tools for comfortable handling while avoiding excessive material removal.

3. Surface Finishing

-

Wet-sand copper with 400-600 grit paper for mirror finishes

-

Polish with appropriate compounds and wheels

-

Apply multiple coats of spindle-turning finish for protection and luster

4. Final Inspection

-

Verify dimensional accuracy with precision measuring tools

-

Conduct visual inspections for surface defects

-

Test sealing performance in actual bottles

V. Final Assembly and Value Realization

1. Peg Installation

Drill 1/8-inch holes for copper rod pegs, securing with CA adhesive while monitoring depth and length for structural integrity.

2. Hardware Attachment

Install selected stopper hardware into threaded inserts, ensuring stylistic coherence.

3. Value Demonstration

Visualize production data through charts showing material performance or heatmaps correlating parameters with quality. Assess production costs, craftsmanship difficulty, and aesthetic appeal to determine market positioning.

Through these meticulously documented steps, artisans can create exquisite copper-wood barrel stoppers while continuously improving efficiency and quality through data-driven process optimization.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!