What is CNC Machined Heat Sinks ?

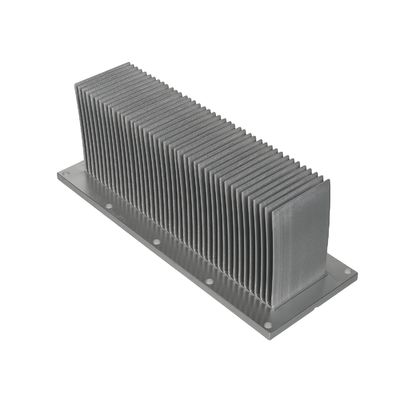

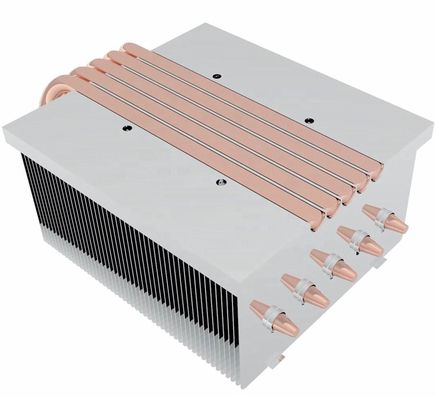

CNC machined heat sinks refer to heat sinks that are manufactured using Computer Numerical Control (CNC) machining processes. Heat sinks are designed to dissipate heat generated by electronic components, such as processors or power modules, to prevent overheating and ensure optimal performance.

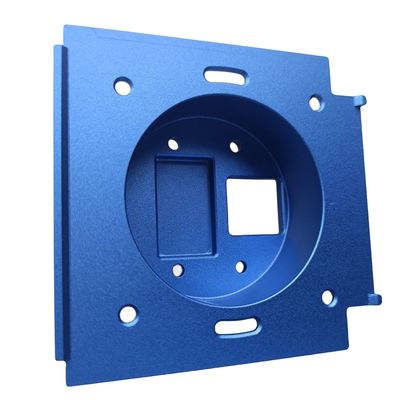

CNC machining is a precise and controlled manufacturing method that utilizes computer-controlled machines to remove material from a solid block or extrusion to create the desired shape and features of the heat sink. The CNC machine follows a programmed set of instructions to precisely cut, drill, and shape the heat sink according to the specified design.

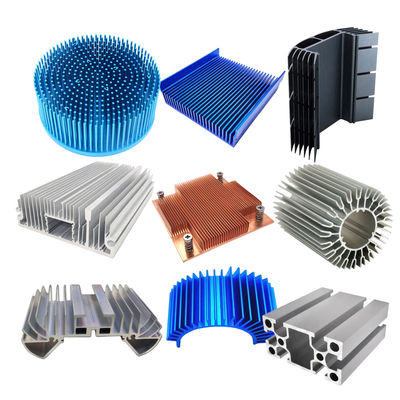

CNC machined heat sinks offer several advantages. Firstly, they allow for complex and intricate designs, enabling the optimization of the heat sink's performance and thermal efficiency. The precision of CNC machining ensures accurate dimensions and tight tolerances, resulting in consistent quality and performance across multiple heat sinks.

Additionally, CNC machining provides flexibility in material selection. Heat sinks can be machined from various materials, such as aluminum, copper, or even exotic alloys, depending on the specific thermal requirements and design considerations.

CNC machined heat sinks are commonly used in applications where high thermal performance, precise dimensions, and customized designs are essential. They find applications in industries such as electronics, telecommunications, automotive, aerospace, and many others where efficient heat dissipation is critical for reliable operation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!