Springs, as fundamental mechanical components, serve critical roles across countless industries. However, as applications grow increasingly complex and precise, standardized spring products often fall short of meeting specialized design requirements. When off-the-shelf solutions prove inadequate, how can manufacturers quickly obtain custom compression springs tailored to exact specifications?

Understanding Custom Compression Springs

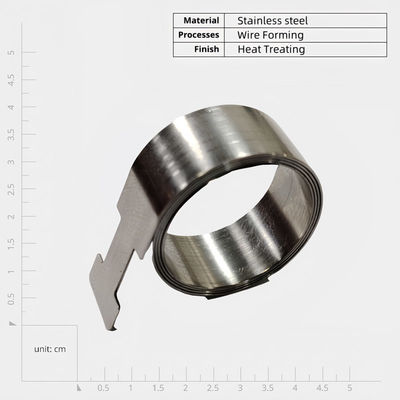

Compression springs are helical elastic components that store energy when subjected to axial pressure and release it when the force is removed. While their operating principle remains simple and reliable, different applications demand variations in dimensions, materials, stiffness, and end treatments. This diversity makes customized production essential for specialized requirements.

Rapid Customization Services

Leading spring manufacturers maintain extensive inventories of standard products while offering rapid customization capabilities. These services typically cover compression springs, wire forms, and stamped components, with compression springs representing a significant portion of custom orders.

Advanced manufacturers integrate engineering and production departments to provide comprehensive support from design through delivery. This streamlined approach significantly reduces lead times while ensuring product quality.

Key Applications for Custom Compression Springs

Precision Instruments

In delicate measurement devices, compression springs provide exact force and displacement control. The confined spaces and strict accuracy requirements of instrumentation frequently necessitate custom spring solutions.

Medical Equipment

The healthcare sector demands uncompromising reliability from components controlling valves, switches, and connectors. Unique material specifications and surface treatments for medical environments often require customized spring designs.

Aerospace Systems

Aviation and space applications push components to their performance limits. Custom compression springs meet extreme weight, durability, and environmental resistance requirements for vibration damping, shock absorption, and critical connections.

Agricultural Machinery

Farm equipment operates under punishing conditions with substantial mechanical stress. Customized springs provide the enhanced durability needed for suspension systems, tension mechanisms, and impact absorption in agricultural applications.

Customization Capabilities

Specialized manufacturers offer diverse compression spring variants including:

-

Ultra-compact designs for space-constrained applications

-

High-pressure models for heavy load scenarios

-

Low-force options for delicate operations

-

Industry-standard compliant versions for regulated markets

-

Heavy-duty configurations for industrial tooling

Additionally, manufacturers can produce springs with unconventional geometries and dimensions to address unique mechanical challenges.

Material Selection Considerations

Material choice critically impacts spring performance. Options include:

-

High-strength music wire for general applications

-

Corrosion-resistant stainless steel for harsh environments

-

Lightweight polymer composites where mass reduction matters

-

Specialty alloys (Inconel, Nimonic) for extreme temperatures

-

Marine-grade metals (Monel) for saltwater exposure

-

Conductive copper alloys for electrical applications

Quality Assurance Standards

Reputable manufacturers maintain ISO 9001 certification and comply with international regulations including RoHS, REACH, and DFARs. Rigorous quality control processes govern material selection, production methods, and final inspection protocols.

Advanced metrology equipment verifies dimensional accuracy, mechanical properties, and surface characteristics to ensure consistent performance.

The Customization Process

A typical customization workflow involves:

-

Technical consultation to define requirements

-

Engineering design and specification development

-

Prototype fabrication for testing and validation

-

Full-scale production upon approval

This structured approach ensures customized springs meet exact operational demands while maintaining manufacturing efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!