Have you ever wondered how those precisely crafted aluminum components - from smartphone casings to drone frames and even critical automotive engine parts - are manufactured? The answer lies in CNC aluminum machining technology. This process transforms raw aluminum into high-precision components through computer-controlled precision.

Understanding CNC Aluminum Machining

CNC (Computer Numerical Control) aluminum machining involves using pre-programmed computer instructions to control machine tools that cut, drill, and mill aluminum into desired components. As a subtractive manufacturing process, it resembles sculpting - removing material from an aluminum blank to achieve the final product.

Compared to traditional manual machining, CNC offers significant advantages:

-

Precision:

CNC machines achieve micron-level accuracy, ensuring components meet exact design specifications.

-

Efficiency:

Capable of 24/7 operation, CNC dramatically increases production output.

-

Consistency:

Identical parts can be reproduced with minimal variation.

-

Complex Geometries:

CNC handles intricate contours and shapes impossible with manual methods.

This technology has become indispensable in modern manufacturing, delivering high-quality aluminum components across industries.

The Aluminum Production Process

Despite being Earth's most abundant metal, aluminum never occurs naturally in pure form. Derived primarily from bauxite ore, its production involves two key stages:

-

Bayer Process:

Bauxite is dissolved in sodium hydroxide, producing sodium aluminate solution. After filtration and precipitation, aluminum hydroxide is calcined into alumina.

-

Hall-Héroult Process:

Alumina is dissolved in molten cryolite and electrolyzed to produce pure aluminum. This energy-intensive process makes aluminum production a power-hungry industry.

The resulting aluminum ingots are processed into various forms (rods, plates, tubes) that serve as raw materials for CNC machining.

Why Aluminum for CNC Machining?

Aluminum's unique properties make it ideal for CNC applications:

-

Lightweight:

At one-third steel's density, aluminum reduces component weight significantly.

-

Strength:

Alloying and heat treatment enhance aluminum's mechanical properties.

-

Corrosion Resistance:

Natural oxide formation and anodizing improve durability.

-

Machinability:

Excellent cutting characteristics reduce production costs.

-

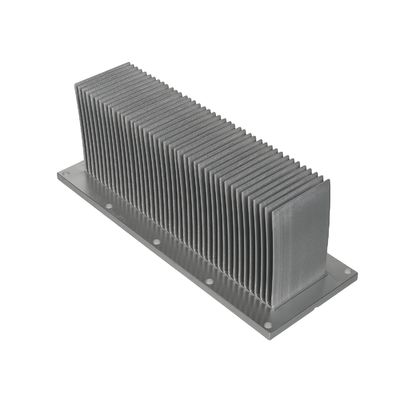

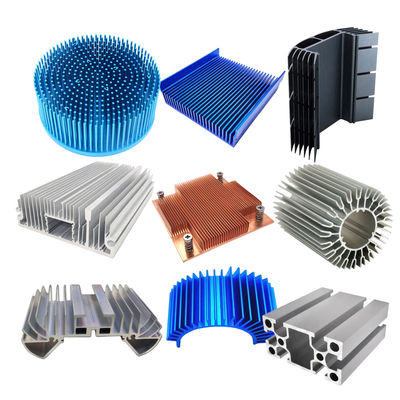

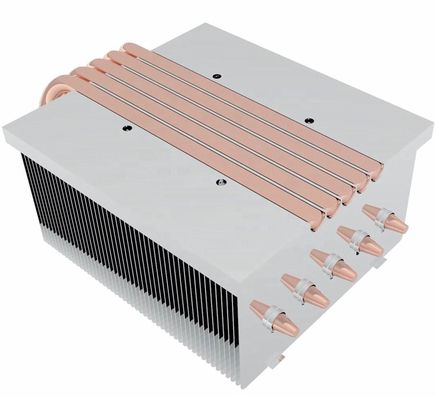

Thermal Conductivity:

Ideal for heat dissipation applications.

-

Recyclability:

Aluminum retains properties through repeated recycling.

-

Cost-Effectiveness:

Balances performance with economic viability.

Optimal Aluminum Alloys for CNC

Selecting the right aluminum alloy is crucial for machining success. Common choices include:

|

Alloy

|

Characteristics

|

Applications

|

|

6061

|

Balanced strength, corrosion resistance, and machinability

|

Aerospace, automotive, electronics

|

|

7075

|

Exceptional strength with reduced weldability

|

Aircraft landing gear, molds

|

|

2024

|

High strength and fatigue resistance

|

Aircraft skins, fasteners

|

|

5052

|

Superior marine corrosion resistance

|

Marine components, chemical vessels

|

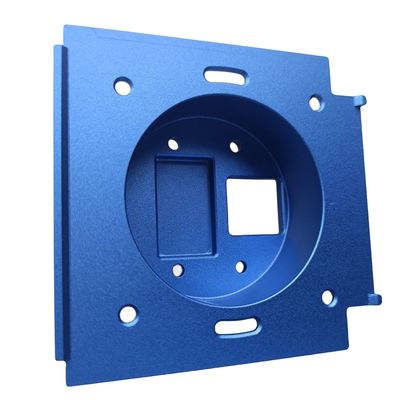

Surface Finishing Options

Post-machining treatments enhance aluminum components:

-

Anodizing:

Creates protective oxide layers (Type II for color, Type III for hardness)

-

Sandblasting:

Produces matte textures and improves coating adhesion

-

Brushing:

Creates linear grain patterns for aesthetics

-

Polishing:

Achieves mirror-like reflective surfaces

-

Powder Coating:

Provides durable, colored protective layers

-

Electroless Nickel Plating:

Deposits uniform protective coatings on complex shapes

Industry Applications

CNC-machined aluminum components serve critical roles across:

-

Aerospace:

Structural elements, fasteners

-

Automotive:

Engine parts, chassis components

-

Electronics:

Device housings, heat sinks

-

Medical:

Surgical instruments, implants

Technical Considerations

-

Tool selection and wear management

-

Chip evacuation and cooling

-

Cutting parameters optimization

-

Workpiece fixturing and stability

Quality Assurance

-

Coordinate measuring machines (CMM)

-

Optical comparators

-

Surface roughness testers

-

Material certification

Future Developments

-

AI-assisted machining optimization

-

Hybrid additive-subtractive systems

-

Advanced cutting tool materials

-

Improved sustainable manufacturing practices

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!